You can use serial number management in SAP S/4HANA Cloud Warehouse Management to identify and track individual products in your warehouse, from goods receipt to goods issue. For products with serial numbers, it is easy to track, even retrospectively, on which date it was delivered from which supplier, who performed the quality inspection, who moved this product, when this was done, and when it was packed and sent to the customer.

A serial number is a series of characters that have been assigned to each product in the warehouse so that it remains separate and are identified in the warehouse system. You can use serial numbers up to a length of 18 characters in an SAP ERP system.

Which serial number profiles are available for SAP S/4HANA Cloud Warehouse Management?

◉ Serial Number Profile A – Serial Number on document item level

◉ Definition: Serial Number Profile A allows you to enter serial numbers for delivery documents: for an inbound delivery item before posting goods receipt or for an outbound delivery item before posting goods issue. However, the serial numbers captured have no further effect – they are not stock managed. After goods receipt, the product behaves as if it did not require serial numbers. You can search for entered serial numbers in deliveries afterwards: However, you cannot see which serial numbers you currently have in stock (only in WM). This serial number profile is good for processes where you only need to find the delivery that the product came into or left the warehouse with. An example is customer returns or complaints: If a customer has a complaint about a delivery, you can look up when they received the product and which supplier it came from.

◉ Advantage: Serial numbers can be entered in Inbound- & Outbound Delivery

◉ Disadvantage: No transparency of serial numbers in stock

◉ Note: It is not possible to define serial numbers as obligatory for goods receipt and goods issue.

◉ Serial Number Profile C – Serial Number on stock level

◉ Definition: Only with serial number profile C is the serial number a part of the stock. (warehouse stock). Only with this serial number profile you can see exactly which serial numbers you have in stock, where they are located and what the corresponding warehouse tasks were. In this way, you achieve full stock transparency and traceability of each individual serial number. However, it also means that you must capture the serial numbers for each warehouse task and for each repacking operation. If you use the full quantity of a quant, this is not necessary, but if you repack or move partial quantities, you must specify exactly which serial numbers are affected. So, it means a significant amount of additional administrative work.

◉ Advantage: Exact information which serial number is stored in which storage bin

◉ Disadvantage: Serial numbers must be entered or confirmed for warehouse task

◉ Note: Serial numbers must be entered before posting goods receipt or goods issue

◉ Serial Numbers in Delivery Processing:

◉ Possibilities to enter serial numbers in inbound deliveries:

● Serial numbers can be received via supplier’s Advanced Shipping Notification (ASN)

● Entered in the inbound delivery in the SAP ERP system

● Entered in the inbound delivery in the SAP EWM system

◉ Possibilities to enter serial numbers in outbound deliveries:

● Entered in the sales order in the SAP ERP System

● Entered in the outbound delivery in the SAP ERP System

● Entered in the outbound delivery order in the SAP EWM System

● Note: Predefined serial numbers in SAP ERP system for e.g., sales order, these serial numbers cannot be changed in SAP EWM system and the corresponding serial numbers needs to be picked

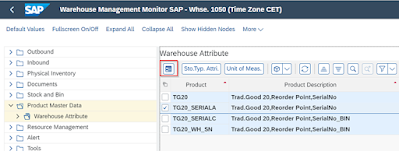

Where to maintain Serial Number Profile for a material?

App: Manage Product Master Data or Change Material (TCODE MM02)

View: Plant Data / Storage 2

No comments:

Post a Comment